Insights

Selection and Challenges of Asset Management System - Part Two

2023-11-13 09:38:56

Selection and Challenges of Asset Management System - Part Two

Advantages of implementation | |

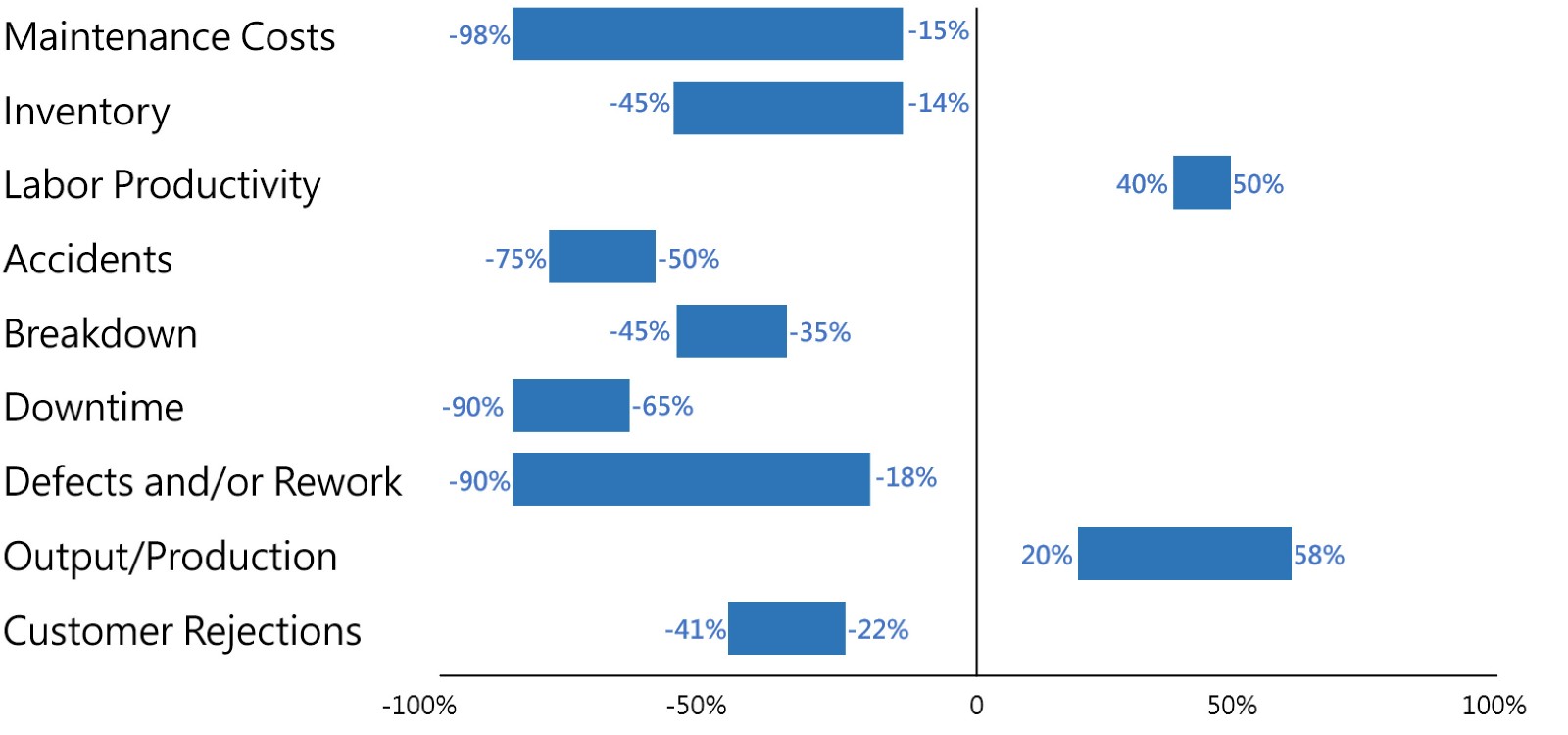

Regardless of the asset maintenance system adopted by an enterprise, the most important thing is to reflect on actual business performance indicators, such as maintenance costs and losses caused by unexpected downtime. According to past research, the implementation of asset management systems can reduce costs by at least 15%, significantly improve production efficiency by more than 40%, and reduce downtime by at least 35%, as shown in Figure 1. | |

Driven by the COVID-19 pandemic and the restructuring of the global supply chain, the importance of asset maintenance in factory operations has become a crucial role. The International Organization for Standardization has also proposed the ISO 55000 standard system for asset management, which includes seven stages: organization, leadership, planning, support, operation, performance, and improvement. The World Economic Forum Lighthouse certification includes digital maintenance as a separate item. This emphasizes the use of data analysis, sensor technology, digital inspection, machine warning, and fault prediction to solve the problem of asset maintenance and repair for enterprises. Even mixed reality and automatic inspection functions can be used, along with remote collaboration, to guide engineers in cross-border asset installation, testing, and maintenance. [7]. | |

| |

Figure 1. The impact of advanced maintenance technology on enterprises [2] |

Development trends | |

The global market size of asset management systems is expected to reach about 57 billion US dollars in 2022 and is estimated to approach 197 billion US dollars by 2030, with an estimated overall compound growth rate of 16.7% [8]. Under the demand for accelerated digital transformation in enterprises after the pandemic, the basic functions of warning maintenance in the past can no longer meet the development needs of enterprises. Through data analysis, optimization of maintenance operations and parts inventory forecasting can be carried out to effectively balance asset reliability and maintenance costs. Even the introduction of self-diagnosis functions and AI artificial intelligence can provide maintenance operation judgments. These system enhancements are all driving forces for improving system requirements. Besides, these estimates are only for capital-intensive industries. | |

As Software-as-a-Service (SaaS) become increasingly recognized and widely used in cross-border operation, the overall application proportion will also grow from the current 20% to 40%. Many system suppliers also provide different functional modules to meet market demand, charging based on the number of users to reduce the initial investment costs required for enterprises to establish asset management systems and increase the willingness to implement systems. | |

Conclusion | |

The biggest challenge for enterprises to implement systems often lies in the burden of old systems and the criteria for evaluating and selecting new systems. Data integration is often a common problem both internally and externally in enterprises. Whether to abolish the old system or upgrade it is often undecided. At the same time, the purpose of using the basic system should be reconsidered. Can it meet the data analysis and warning functions required for enterprise operations and development, effectively reduce downtime and maintenance costs, and even provide the best maintenance route and operation mode? When should maintenance/replacement/repair and replacement of parts be carried out to effectively extend the lifetime of an asset and provide visualized data analysis charts to clearly understand the maintenance progress of the asset? These are all issues that corporate management should consider. Enterprises can refer to the suggestions provided for the core functions of the system and the necessity of auxiliary functions according to their industry characteristics to select asset management systems. |

Author

Dr. Albert Liao

Founder and CEO of Wareconn Technology Services (wareconn.com),

Author of “Warranty Chain Management - Digitalization and Sustainability”, Springer

Reference

- Komonen Kai, 2002, A Cost Model of Industrial Maintenance for Profitability Analysis and Benchmarking, International Journal of Production Economics, 79, 15-31.

- Douglas Thomas, Brian Weiss, (2021), Maintenance Costs and Advanced Maintenance Techniques in Manufacturing Machinery: Survey and Analysis, International Journal of Prognostics and Health Management.

- Albert Liao, (2022),Warranty Chain Management - Digitalization and Sustainability, Springer.

- Jay lee, Jun Ni, Jaskaran Singh, Baoyang Jiang, Moslem Azamfar, Jianshe Feng, (2020), Intelligent Maintenance Systems and Predictive Manufacturing, Journal of Maufacturing Science and Engineering, Nov. Vol.142, 1100805-1.

- Kristian Steenstrup, Nicole FoustMarket, (2021), Guide for Enterprise Asset Management Software, Gartner, ID G00742599

- Juliana Beauvais, John Villali, Reid Paquin, Andrew Meyers, Kevin Permenter, (2020), IDC MarketScape: Worldwide SaaS and Cloud-Enabled Asset-Intensive EAM Applications 2020–2021 Vendor Assessment, IDC # US46261320e.

- World economic Forum, (2023), Global Lighthouse Network: Shaping the Next Chapter of the Fourth Industrial Revolution.

- Next Generation Technologies, (2020), Enterprise Asset Management Market Size, Share Report.