Warranty service is an important component of the warranty provider's business operations, and accurate warranty forecasting is a driving force customers satisfaction. Statistical analysis of warranty data, after-sales evaluation of product quality, and using warranty data to realize reverse logistics have long been neglected by warranty providers. A large amount of available information is hidden in massive warranty data yet it is difficult to effectively mine and hard to provide reliable references for the warranty provider's operational strategy.

The operation status of the enterprise's internal assets directly affects the production capacity and efficiency. Accurate fault prediction can demonstrate the enterprise's efficient production and operation. Long fault intervals, lost repair data, and unrecorded repair data make it difficult to analyze and organize asset repair data, and leads to difficulties for operators to understand status of the asset.

The Data Analysis can effectively solve the difficult problems of collecting, checking, and analyzing warranty data for users. It provides professional data processing and adds value to the data by analyzing it.

The Data Analysis function is mainly divided into six stages: data statistics, quality analysis, part statistics, warranty forecasting, warranty costs, and strategy-making:

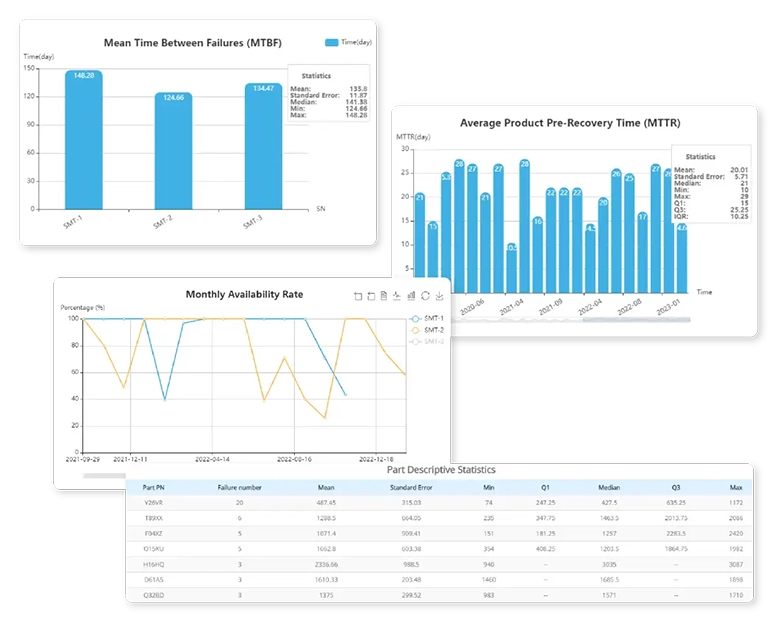

By filtering the massive data generated by warranty management and repair services, data counting and analysis are conducted to show the quantity of warranty claims by product, batch, machine, and part through charts.

Based on warranty data supplemented by manufacturing data, the quality of products is effectively analyzed to provide a solid and effective basis for process improvement and quality enhancement.

Obtain part replacement records and calculate part quality data to provide data basis for part replacement and estimation, and pre-stock based on the actual usage of parts to effectively shorten the waiting time.

Apply mathematical models to scientifically forecast future warranty and spare parts quantities, while maintaining high customer service levels, effectively control inventory investment, and increase asset return rates.

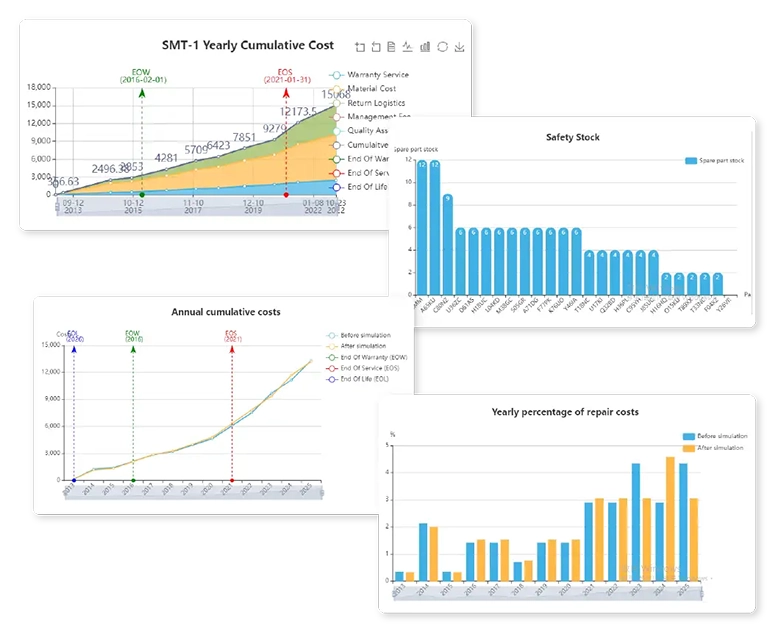

Adjust different service parameters using scientific forecast. Provide optimal cost-effective solutions through simulating warranty conditions and improve strategic decision-making accuracy.

Accurately control the occurred and estimating warranty costs.

wareconn will satisfy your imagination of warranty service information mining with its complete Data Analysis function.

Analyze repair data from multiple dimensions and enhance data visualization.

Statistically calculate the MTBF and failure rate of products, to strengthen product quality control.

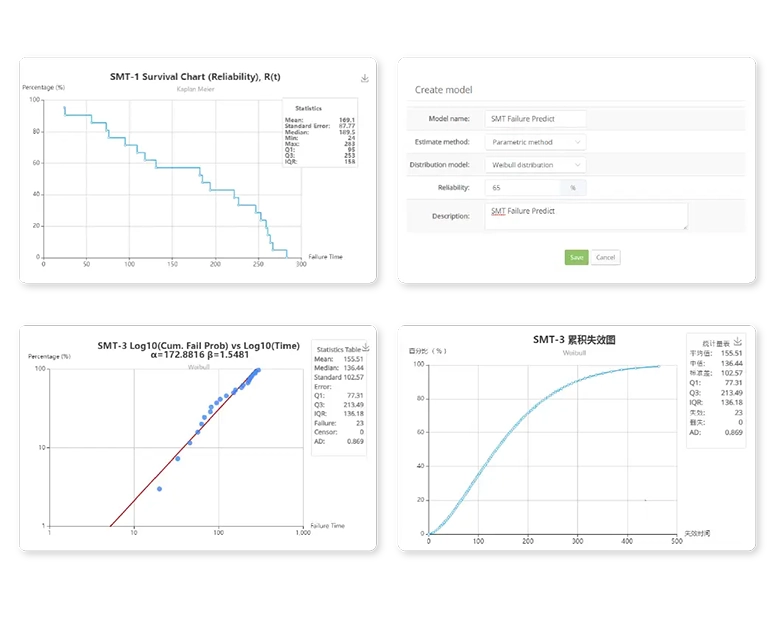

Using Weibull distribution model to forecast the next failure time or future warranty claims quantity and reduce operating costs.

Estimate the spare parts quantity based on the procurement cycle and safety stock coefficient to reduce costs and inventory.

Calculate the warranty costs and estimate future costs to reduce operational risks.

Simulate warranty settings, calculate and compare the expected costs before and after simulation as a strategy reference.

Create a data set

Build a massive data foundation

Fetch or upload shipping data

Bedding quality analysis

Get useful information from massive warranty data

Professional process warranty data

Analyze the warranty quantity based on factors such as customers and part numbers

Filter and process valid warranty data

Analyze defective batches based on factors such as batches and months of service

Filter and process valid warranty data

Analyze product defects and draw Pareto diagrams based on customer statement and warranty diagnosis

Solve diverse data types

Filter the warranty data of the parts under the product

Realize data value-added

Filter batch actual shipment data

Multi-dimensional statistical analysis of the failure rate of a batch

Filter actual product shipment data

Multi-dimensional statistical analysis of the failure rate of a product

Organize and analyze the effective data of the components under the product

Plot the frequency distribution of component failure time

Analyze the reasons for the failure rate

Combine shipping information and platform data

Customized analysis chart

Provide prediction model building conditions

Support multiple prediction model options

Weibull, three-parameter, index and other algorithms

Data mining, processing, analysis

Use mathematical models to estimate future warranty numbers and improve forecast accuracy

Optimize inventory indicators

Refer to the scrap rate and monthly production capacity to estimate the inventory of spare parts and improve the return on inventory assets

Historical warranty cost data collation

Analyze data according to products and customers

Relying on model prediction logic

Estimate future maintenance costs

Add future shipment data

Calculate the total cost of repairs for all shipments

Data science practical applications

Improve decision-making activities

Simulate warranty settings to obtain the best solution

Setting warranty and shippingdata

Filter valid data from massive data, and query warranty information at multiple levels

Analyze product quality from multiple dimensions through data processing.

Create and select models, use different models for the data and come out with different information.

Predict future warranty based on the statistics or even compare different models for the best result.

Input procurement cycle and safety stock coefficient, forecast spare part demand and calculate safety stock based on future warranty.

Classify and calculate warranty costs occurred, forecast the future to assist strategy-making

Forecasting and simulating reverse service to achieve maximum benefits

Users can select the data to analyze from the massive warranty data generated by WM and RS, filter and restructure them into a data set that can be analyzed and forecasted. After obtaining the data, users can apply data verification function and obtain meaningful analysis results.

Automatically generate statistical graphs for product lifecycle, failure code, and product batch repair quantity based on the established dataset. It can also perform statistical analysis on part replacement quantity and lifespan. Users can complete preliminary data analysis based on the charts.

Data analysis can quickly calculate quality indicators such as MTBF, reliability rate, product failure rate, WCR, etc. and generate quality graphs from multiple dimensions such as product, batch, machine, part, month, etc., helping users understand the product quality and identify the issues accordingly.

The data analysis function applies both non- and parametric methods to establish exclusive failure models for each machine/product. Among them, the parametric method applies the Weibull distribution model widely used in reliability engineering to forecast failures or repairs. Users can perform maintenance or quality improvement in advance based on the results.

The platform can calculate and analyze all the expenses occurred in the repair process, and categorize and graph them accordingly. It can also forecast the costs based on the results of warranty and spare parts. wareconn also has a warranty simulation function, where users can adjust the warranty period, item costs, and product quality data based on the conditions in order to assist in making warranty strategies for new products.

Copyright © 2025 Wareconn Technology Services, All Rights Reserved.