Insights

Impact of the EU Right to Repair Proposal on Enterprises-Part Two

2024-10-17 16:41:05

Impact of the EU Right to Repair Proposal on Enterprises-Part Two

Impact on Enterprises | |

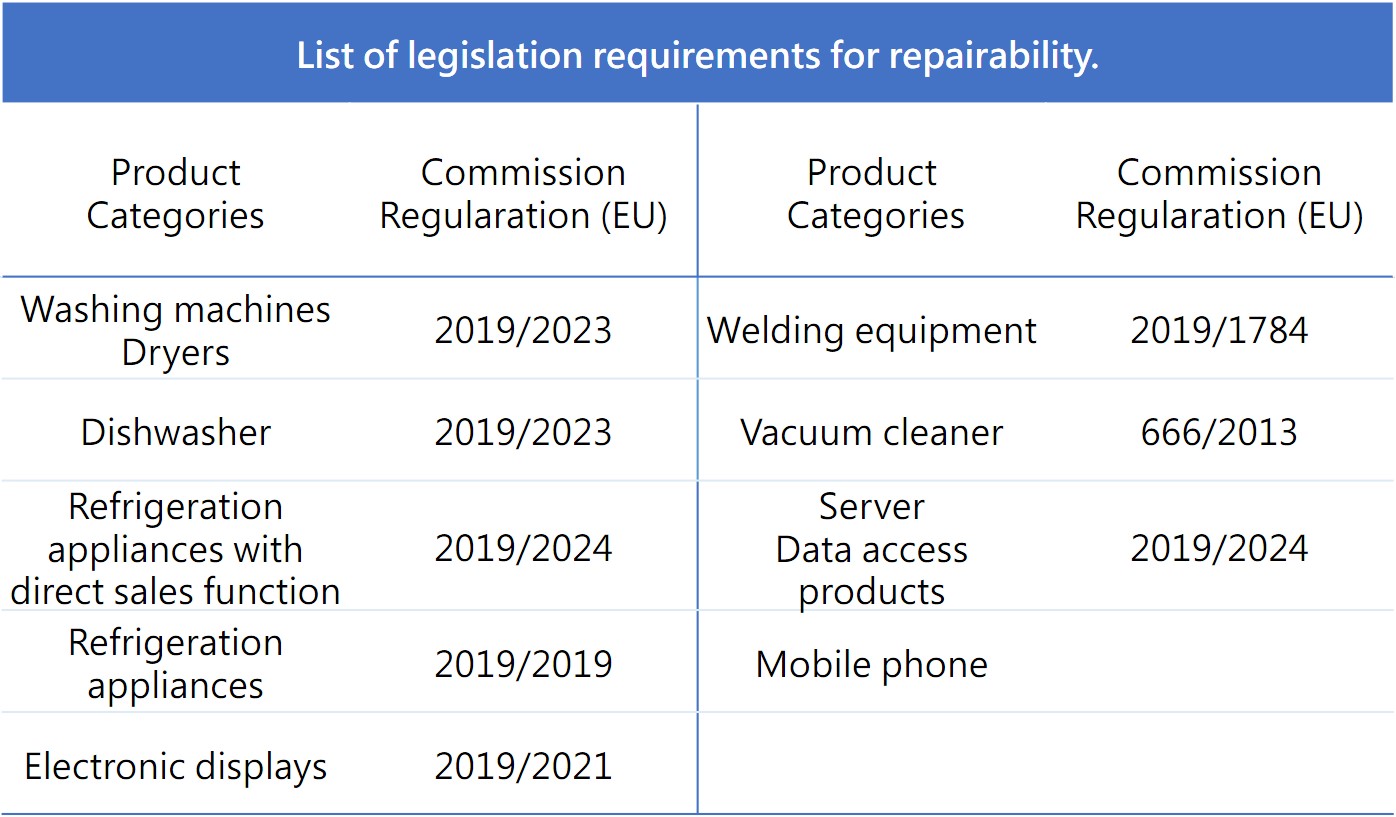

In order to effectively reduce the resource waste and environmental pollution caused by discarded electronic products, the proposed right-to-repair legislation currently targets 52.7% of white goods, 14.6% of consumer electronics and screens, and 14.1% of information and communication equipment, detailed list as shown in Table 1. The proposal's impact mainly revolves around the producer of regulated products, as well as stakeholders such as manufacturers, importers, dealers, independent repairers, and companies and related transaction management platforms involved in refurbishing and recycling. | |

| |

Table 1: Impact of advanced maintenance technology on enterprises [2] | |

The impact on producers in the product warranty period should not be significant, as they still need to provide repair or replacement services as per contract, with repair taking top priority. However, managing products outside of the warranty period requires an understanding of the extension of obligations under this proposal, including the provision of repair services and skills, corresponding control of repair costs and spare parts, which producers will face to varying degrees. As demand for repair services increases, the repair/refurbishment industry will be significantly affected. Increasing repair can help improve competitiveness and effectively improve product design and reliability by leveraging user experience. Increased repair activities can also benefit various repair service providers, including independent repairers and small and medium-sized enterprises, as well as producers and traders providing spare parts and repair services. |

| |||

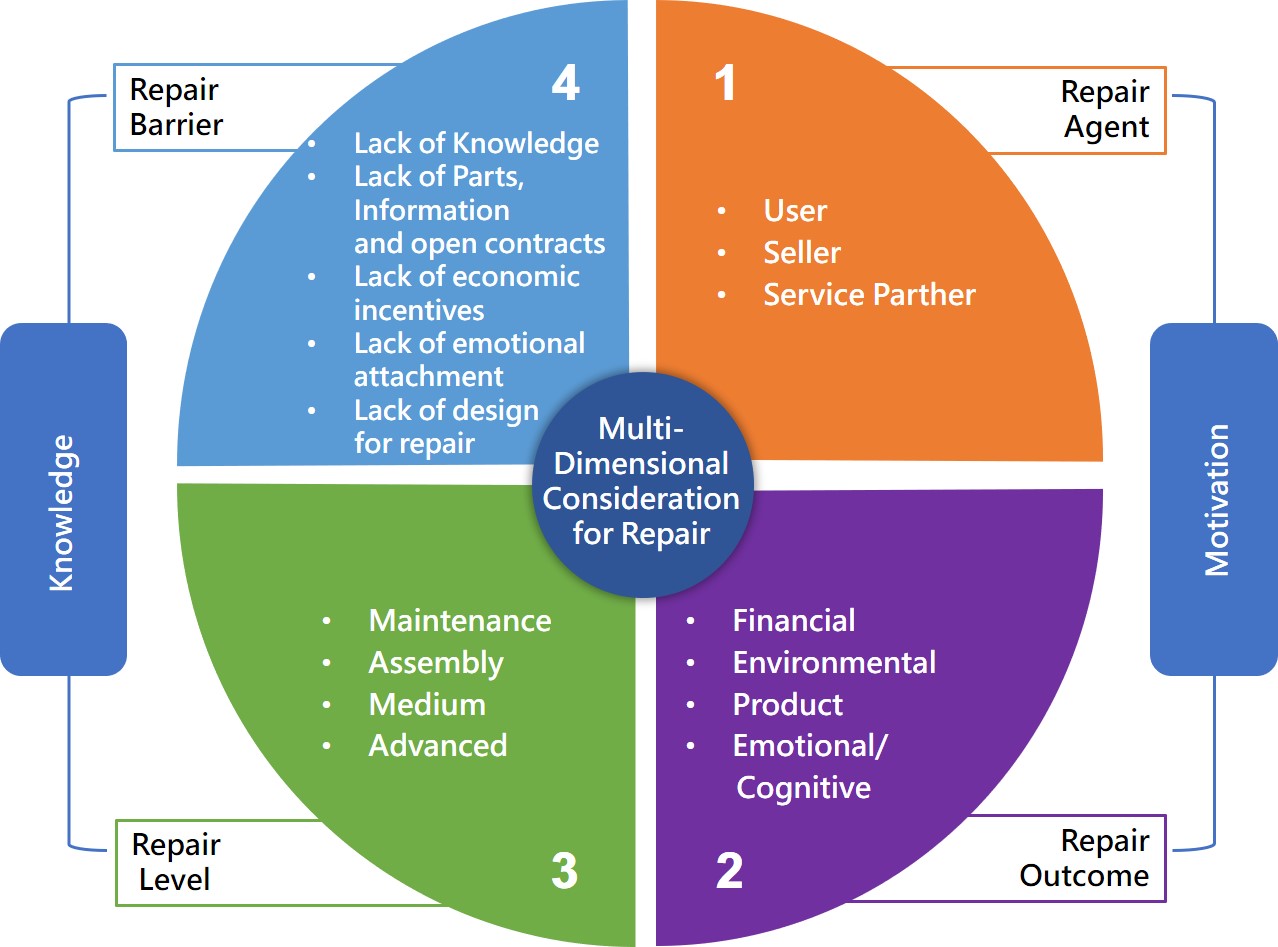

Figure 3: Multi-dimensional considerations for EU repair [8] | |||

Whether consumers take repair action is a multi-dimensional consideration, with obstacles, levels, operations, and incentives all significantly affecting whether the right to repair can truly implement a circular economy. As shown in Figure 3, the new proposal aims to enhance repair incentives and effectively reduce obstacles in terms of technology, costs, operational convenience, and insufficient spare parts management. From the perspective of producers, the main impact analysis is on how to build a circular economic system in response to the new proposal, with an expected increase in repair demand and a relative reduction in product sales. According to an analysis of repair costs in the Warranty Week report, corporate revenue will shift from sales to service by about 1.5%, but the benefits obtained will be user stickiness and opportunities for repeat sales, with the durability and quality of products gaining greater trust. Refurbishing services can also extend the customer base and market, making corporate sales more visible. To achieve this goal, the corresponding service organization and management will face considerable challenges, including: | |||

| > | Extending and sharing repair skills | ||

| > | Control of spare parts inventory | ||

| > | Linking after-sales service and repeat sales | ||

| > | Consolidating after-sales management data analysis | ||

In addition to the challenges in after-sales management, companies also need to consider repairability and commonality in product design, effectively reducing repair obstacles and designing modularization for different components base on reliability to avoid entire products being irreparable due to the failure of minor components. Of course, the update of software and firmware can also be used to implement new functions instead of disposing of and purchasing new products. In addition to effectively understanding user usage outside the warranty period, the provision of service can also help understand the reliability of products, which has a significant impact on the selection and design of components suppliers in the manufacturing process. The right to repair proposal is an extension of obligations for enterprises, as well as an opportunity to enhance user stickiness, achieve repeat sales, and improve quality. | |||

Strategy | |||

Whether it is the EU's construction of an ecological design framework for sustainable products or proposals to encourage consumers to undergo green transformation, both are driving the entire market to enhance repair incentives, maximize the value of product use, and avoid premature scrapping of products. The ecological design parameters of products no longer only emphasize the use of recycled materials, but also include durability and reliability of the product itself and its components, ease of repair exercise of the right to repair, compatibility, and spare parts preparation, as well as convenience of software updates, reuse, remanufacture, and refurbishment. For enterprises, all of these indicators are prepared to establish a circular supply chain, as shown in Figure 4. | |||

| |||

Figure 4: Circular supply chain system [8] | |||

The proposal for the right to repair hopes to bring the EOS (End of Service) - the end of the service period - as close as possible to EOL (End of Life) - the recycling and scrapping period. At the same time, all products for reuse and resale can receive reasonable repair and platform management to avoid becoming warranty orphans with no corresponding repair resources, as shown in the yellow area of Figure 4. It can be understood that the right-to-repair proposal presents challenges for enterprises' after-sales service and is also an important direction for sustainable business operations. To achieve this goal, strategies include: | |||

> Establishing a circular supply chain | |||

> Cooperation in resale platforms | |||

> Establishment of after-sales full-process management system | |||

> Strengthening failure data analysis and feedback mechanisms | |||

In the process of establishing a circular supply chain, particularly in repair systems, the connections can be created through relevant technical documentation and the trade of spare parts, as well as collaboration with service centers (whether internally organized within the company or through partnerships with external independent repair centers). This approach allows for effective control over technology and the implementation of post-warranty obligations. Concurrently, collaboration with resale platforms facilitates increased utilization of repaired products. These efforts serve as additional sources of revenue for businesses, potentially compensating for reduced opportunities in new product sales due to enhanced repair practices. | |||

The connections between the repair service centers can be managed through the enterprise's internal system or the system established by the right to repair proposal for member countries, or even outsourced to an independent platform for unified management. The establishment of these systems must be able to link enterprise after-sales warranty management data and provide full-process tracking. In a unified platform environment, repair data analysis and quality statistics can be performed. These are important strategies for enterprises to better understand market feedback, user experience, product durability, and reliability. | |||

Conclusion | |||

Producers have long used various intellectual property, safety, design, and cost obstacles to prevent consumers from repairing their own products or using independent repair services, resulting in premature scrapping of electronic equipment. In the U.S., President Biden signed a sweeping executive order in July 2021 directing the FTC to draft new right-to-repair regulations, and various U.S. states have passed some version of right-to-repair legislation [9]. Increasing numbers of "right to repair" legislative movements are trying to make it easier and cheaper for consumers to repair their products by requiring producers to share repair information, provide diagnostic tools and supply repair parts, and increasing transparency in repair services. In addition to avoid unnecessary waste, the rise of environmental awareness and climate change make it urgent to establish a circular economy, which is also the main reason why the right to repair legislation has received attention. After the legislation is passed, it will inevitably have an impact on enterprise operations, and early recognition of the direction of the scope of the right to repair, timely adjustment of relevant organizational resources and processes, will help establish a sustainable business environment. | |||

Author

Impact of the EU Right to Repair Proposal on Enterprises-Part Two.pdf

Reference

- European Commission, 2023, Proposal for a Directive of The European Parliament and of The Council – on common rules promoting the repair of goods and amending Regulation (EU) 2017/2394, Directive (EU) 2019/771 and (EU) 2020/1828

- PRIG, Right to Repair, 2023, https://pirg.org/campaigns/right-to-repair/

- Florin-Constantin MIHAI, Maria-Grazie GNONI, Christia MEIDIANA, Chukwunonye EZEAH, Nigeria Valerio ELIA, 2019, Electronic Waste Management and Treatment Technology - Waste electrical and electronic equipment (WEEE): Flows, quantities and management, a global scenario”, Elsevier Science & Technology.

- Emissions Gap Report, 2022, The Closing Window Climate crisis calls for rapid transformation of societies, UN Environment programme.

- European Commission, 2023, Commission Staff Working Document – Impact Assessment Report, Proposal for a Directive of The European Parliament and of The Council – on common rules promoting the repair of goods and amending Regulation (EU) 2017/2394, Directive (EU) 2019/771 and (EU) 2020/1828.

- European Commission, 2023, Proposal for a Regulation of The European Parliament and The Council- establishing a framework for setting ecodesign requirements for sustainable products and repealing Directive 2009/125/EC.

- European Commission, 2023, Proposal for a Directive of The European Parliament and The Council – amending Directive 2005/29/EC and 2011/83/EU as regards empowering consumers for the green transition through better protecting against practices and better information.

- Albert Liao, (2022),Warranty Chain Management - Digitalization and Sustainability, Springer.

- Luyi Yang, Chen Jin, and Cungen Zhu, 2023,Research: The Unintended Consequences of Right-to-Repair Laws,Harvard Business Review.