*IDC (2021) Worldwide Asset Performance Management Software Forecast, 2021–2025: Market Growth Momentum Propelled by Ecosystem Expansion

With repair centers all over the world, traditional operations cannot respond to users' repair requests in a timely manner and manage repair operation information, including repair progress and spare parts management, which has become a challenge that brand owners need to solve.

Use wareconn platform to handle the repair progress of global service centers in real time, and implement spare parts inventory management. And the system's automatic warning helps to prepare parts in advance. The platform can be used to manage service centers and suppliers in various regions, and further analyze the repair records, so as to discover potential problems and room for improvement of product quality, performance, reliability and customer satisfaction.

Due to the system incompatibility, the test report of the service center for the repaired product needs to be manually recorded and sent by email. In addition to being time-consuming and inefficient, it is also prone to human error.

Through the wareconn platform, the repair center can record and compile the test data of the returned product in real time, and automatically connect it back to the brand's database through the API. Brand owner only needs to view the reports from their own systems, no additional import jobs are required. 100% automatic operation, saving manpower and improving process efficiency, and realizing systematic and instant operation tracking management of the entire warranty process.

The operation management systems of brand and suppliers are incompatible. When there is an RMA application, manual review is required, and the response time can be very long, and is impossible to respond to the demand immediately. The management of spare parts and the logistics of returned goods also require manual operation, which means it is difficult to track the repair history.

wareconn helps to sort out the whole process of after-sales service in the service center and can be connected with the customer's internal system. The customer only needs to submit the warranty application in the internal system, and send it back to wareconn through the API interface. The progress will be automatically created and approved. The administrator accounts can be assigned according to requirements, so that the RMA of 309 data centers around the world is not limited by time difference, and can be effectively managed 24/7. Global spare parts management will be carried out, and advanced exchange replacement can be taken place to shorten the service time. Statistical summary functions such as service report and defect records can help suppliers review and improve product quality.

Procurement and maintenance contract of asset management by using traditional Excel and paper work, without filing and classification, and it is difficult to check the warranty period or out-of-warranty. Inspection, maintenance, self-maintenance and supplier repairs are recorded separately, and there is no summary and serial unified tracking statistical KPIs. It is difficult to calculate the quantity, amount, repair and other costs of spare parts after the manufacturer's door-to-door service and replacement.

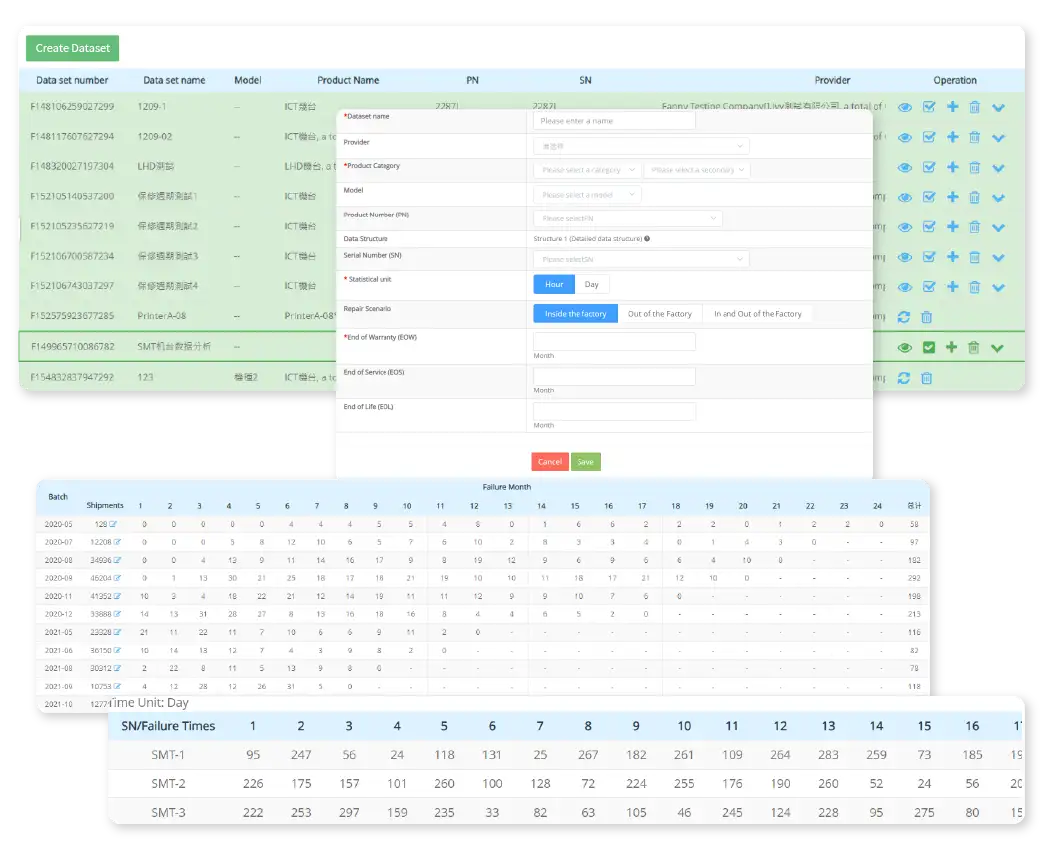

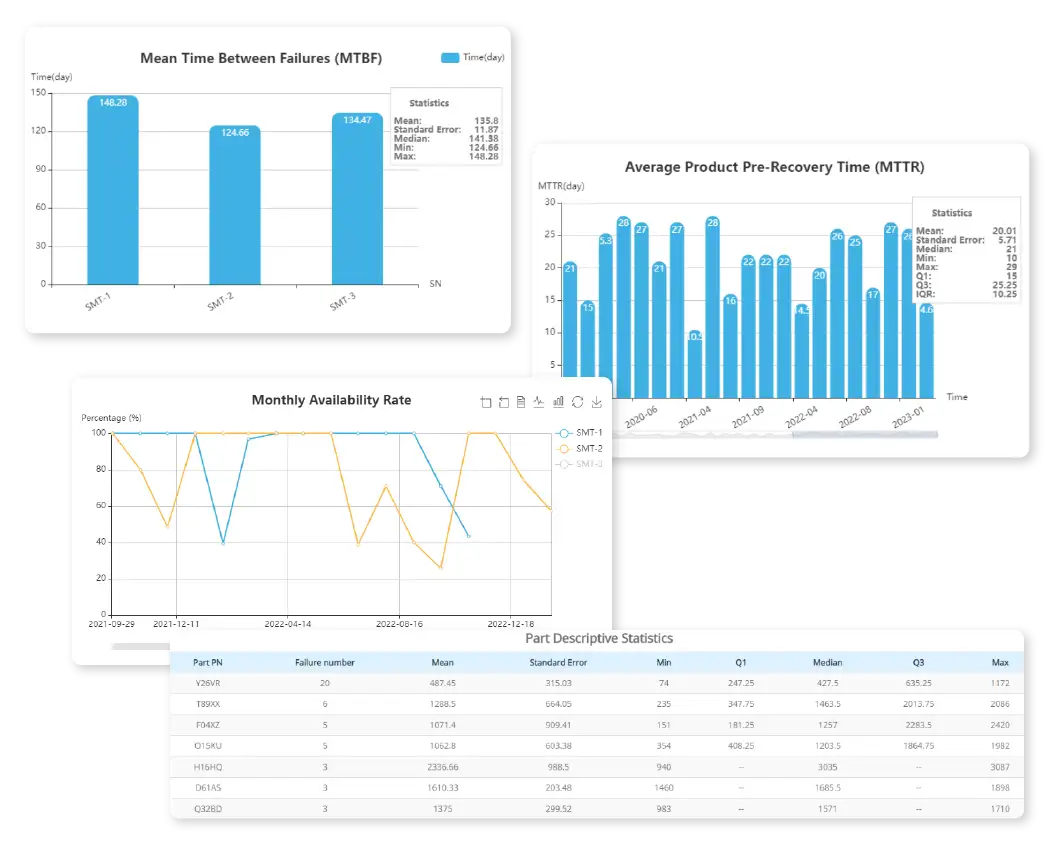

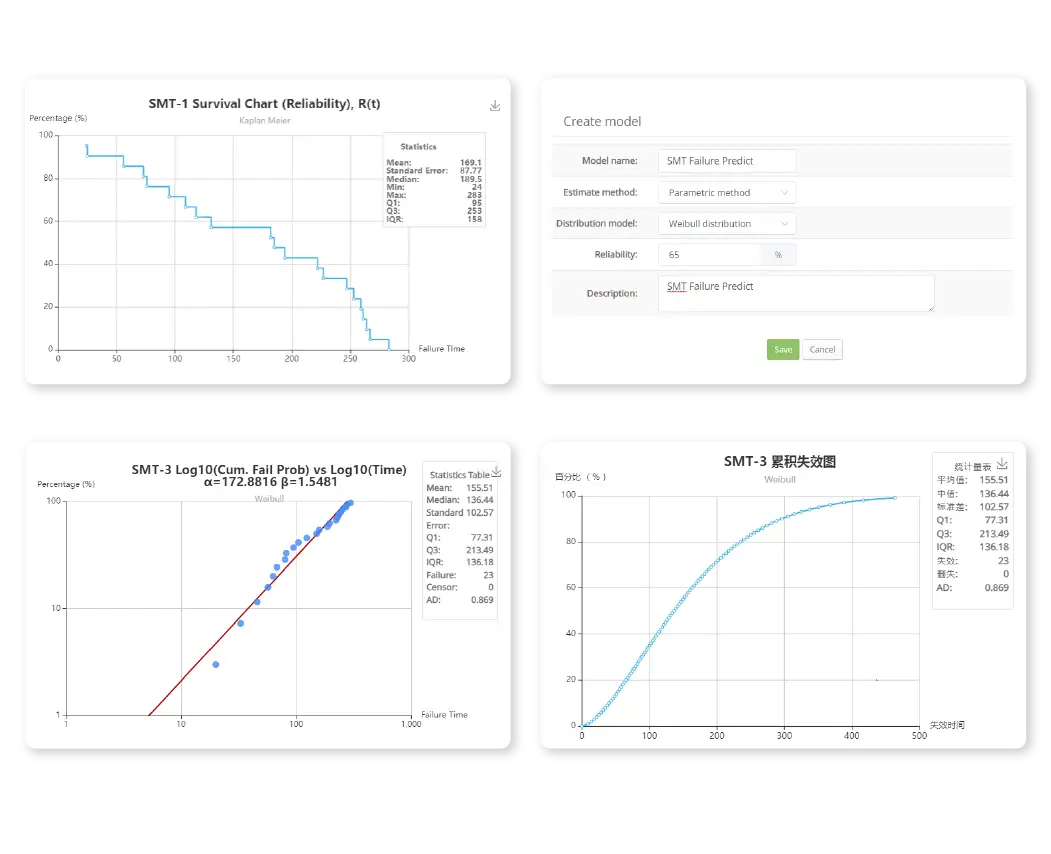

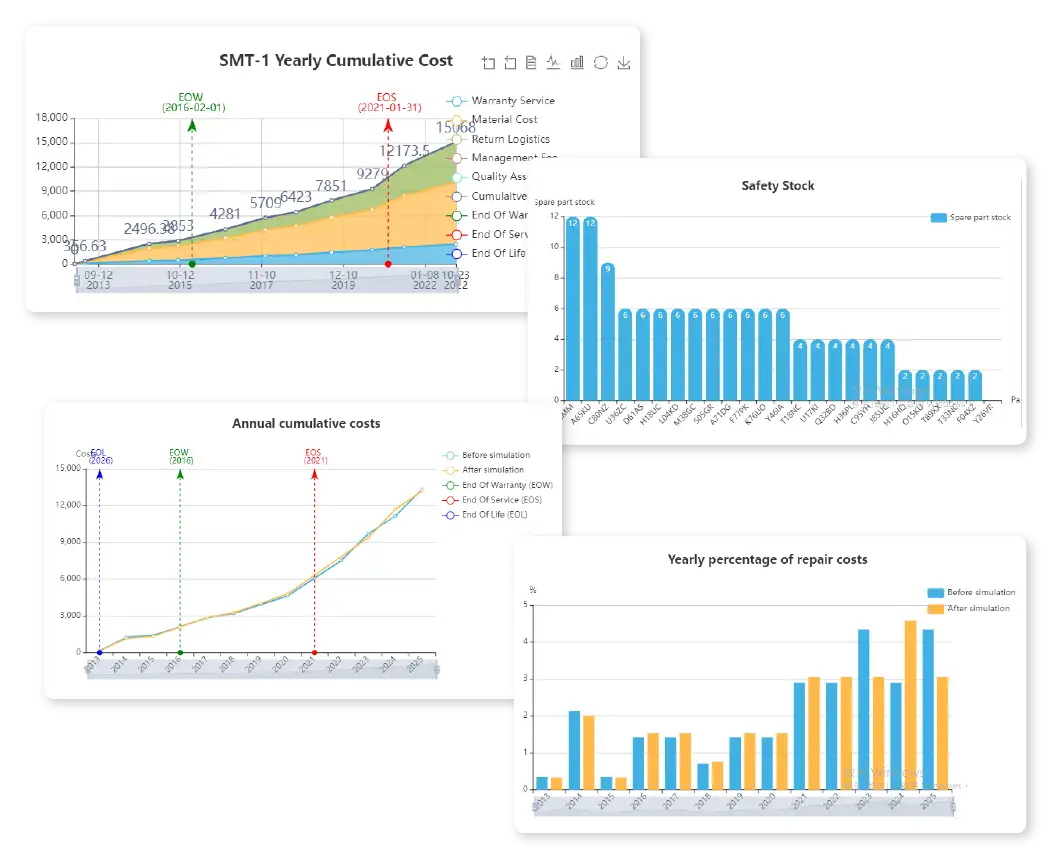

Using the wareconn and the Asset Management APP, the contract management function is connected in series from the installation, contract, daily maintenance, self-maintenance records, and supplier maintenance records. Actively drive repair and maintenance to achieve the purpose of early warning maintenance. And using statistical analysis for all records to generate visual graphs, get product reliability analysis, MTBF/MTTR, and trigger automatic reminders to reduce risks. Through the asset management solution, the production and operation efficiency can be improved, the manual work hours is reduced by 80%, and the inventory turnover cycle can be reduced by 40%.

Difficult to manage and track historical service records

Scattered offline Excel records, resulting in consolidation inconvenience

No systematical collection on analysis report from OEM/ ODM

Easy to lose quality report from different customers

Handle batch RTV business by clicks

Available to eliminate unecessary return with failure analysis procedure'

No systematic management for the warranty contract between customers and suppliers

Unavailable to track the service status

Spend much time on expense settlement and chart creating

Inconvenient to real-time track the operation progress

Deploy relaible gloabal service network

Simplify servicing process by integration and purify warranty management by automation

No system records the warranty information of all asset and spare parts

Easy to lose paper file maintenance reports

Messy cost settlement operation and difficult to summarize the quality status

Unable to manage the entire warranty process in one system

Clear warranty information on every asset

Warranty claims, contract management, service record and bills are avaialbe to share on one-stop platform

No connection between manufacturers and service center to make preparations in advance

Chaotic process on the defective and spare parts delivery process

Separate and various service report to be mailed repeatedly or omitted

Manual summarize the maintenance costs and charts analysis

Enhance everything by change nothing

Combine world-wide service resources and cooperate with build-in systems

Unavialble to summarize various maintenance information in time, and find out the batch defectives immediately

Delayed communication on the physical maintenance data

Manual maintenance data is difficult to find historical record

Difficult to predict product return and prepare fixtures and manpower arrangements in advance

Fulfill data consolidation and transparency

Save communication time and find out the core value of warranty claims

Global AI server shipments are projected to grow by more than 20% annually by 2026, accounting for 17% of the overall server market...

TrendForce, a global market research firm, has compiled a list of ten key trends for the development of the technology industry in 2026. See the article for details.

Taiwan’s Foxconn has secured regulatory approval to inject an additional $569 million into its Wisconsin operations, a move that signals both the company’s renewed commitment to U.S. manufacturing and the rising strategic value of AI server production.

Automation helped shape the First Industrial Revolution – and it continues to evolve in today’s Fourth. While automation has long been part of the manufacturing landscape, recent advances in artificial intelligence, vision systems and robotics hardware are enabling a new generation of more intelligent and adaptable machines.

Engineering teams can leverage AI to analyze logs, detect anomalies, and streamline decision-making processes for better system reliability.

26 August 2025, Taipei, Taiwan – Hon Hai Technology Group (“Foxconn”) (TWSE:2317) is adopting NVIDIA RTX PRO Servers, an enterprise level data center infrastructure accelerated by NVIDIA RTX PRO 6000 Blackwell Server Edition GPUs. Foxconn will use NVIDIA RTX PRO Servers to accelerate GenAI deployment, agentic workflow design and simulation applications.

Institutions such as the IEA stress the urgency of transitioning away from energy-intensive processes, while governments and leading tech companies worldwide have set net-zero roadmaps.

Between upgrades and breakdowns to cellphones, tablets, laptops, and appliances, so many electronic devices are getting tossed in the trash that they've taken on a name of their own: e-waste.

In today’s digital economy, organizations operate far beyond traditional office boundaries. Applications and services run across global networks, moving data widely to deliver speed, scale, and performance.

In response to the ESG trend, enterprises are actively promoting energy-saving and carbon reduction management, especially in the environment of global supply chain restructuring. While considering energy-saving, are they also facing challenges in effectively managing assets? With the rise of Industry 4.0, the management mindset under the demographic dividend of the past few years may also need to accelerate digitization. In addition to implementing Manufacturing Execution System (MES), how should the corresponding asset management system be selected? Is it just to digitize asset management-related operations (inspection, maintenance, repair), or can it effectively improve asset reliability, reduce unexpected downtime, and even improve asset utilization value through data analysis of asset maintenance processes? Research indicates that asset maintenance costs can account for anywhere from 0.5% to 25% of enterprise revenue [1]. The choice of digitized system management will seriously affect the enterprise's operating performance and profitability.

Under the guidance of Industry 4.0 and intelligent technology, the era of emerging technology trends has arrived. Whether it is robot technology or artificial intelligence, automation, advanced materials and manufacturing, the Internet of Things, cloud co

Under the drive of the Industry 4.0 era, the basis of the corresponding transformation opportunities for after-sales service lies in data. Whether it's enterprises focusing on the development of connected products, the transformation of XaaS business model, digital transformation, installation excellent, resilient supply chains, omni-channel services, the deployment of digital twins as service enablers, or providing intelligent analytics, these all increase the importance of warranty data acquisition and analysis. Especially when facing the emergence of new technology products, geopolitical supply chain reorganization, and the shift of the customer experience economy, the overall industry strategy is gradually shifting from product-centric to customer-centric intelligent experiences[1].

Under the guidance of Industry 4.0 and intelligent technology, the era of emerging technology trends has arrived. Whether it is robot technology or artificial intelligence, automation, advanced materials and manufacturing, the Internet of Things, cloud co

In response to the ESG trend, enterprises are actively promoting energy-saving and carbon reduction management, especially in the environment of global supply chain restructuring. While considering energy-saving, are they also facing challenges in effectively managing assets? With the rise of Industry 4.0, the management mindset under the demographic dividend of the past few years may also need to accelerate digitization. In addition to implementing Manufacturing Execution System (MES), how should the corresponding asset management system be selected? Is it just to digitize asset management-related operations (inspection, maintenance, repair), or can it effectively improve asset reliability, reduce unexpected downtime, and even improve asset utilization value through data analysis of asset maintenance processes? Research indicates that asset maintenance costs can account for anywhere from 0.5% to 25% of enterprise revenue [1]. The choice of digitized system management will seriously affect the enterprise's operating performance and profitability.

Under the drive of the Industry 4.0 era, the basis of the corresponding transformation opportunities for after-sales service lies in data. Whether it's enterprises focusing on the development of connected products, the transformation of XaaS business model, digital transformation, installation excellent, resilient supply chains, omni-channel services, the deployment of digital twins as service enablers, or providing intelligent analytics, these all increase the importance of warranty data acquisition and analysis. Especially when facing the emergence of new technology products, geopolitical supply chain reorganization, and the shift of the customer experience economy, the overall industry strategy is gradually shifting from product-centric to customer-centric intelligent experiences[1].

On March 22, 2023, the European Commission officially adopted a new proposal Right to Repair (R2R), which is a common rule advocating for product repair by reducing waste to save consumers expenses, while supporting the goal of sustainable consumption under the European Green Deal [1].

On March 22, 2023, the European Commission officially adopted a new proposal Right to Repair (R2R), which is a common rule advocating for product repair by reducing waste to save consumers expenses, while supporting the goal of sustainable consumption under the European Green Deal [1].